Accelerating Innovation With Precision: Prototyping At Spartech's Innovation Center

Accelerating Innovation With Precision: Prototyping At Spartech's Innovation Center

Recognizing the importance that our customers place on speed to market, we distinguish ourselves with our comprehensive expertise, advanced equipment, and state-of-the-art facility.

At Spartech, we dedicate ourselves to accelerating our customers' product development processes with precision, efficiency, and value.

Our mission is to help our customers improve quality, optimize costs, reduce development cycle times—and deliver outstanding prototypes that exceed expectations. Recognizing the importance that our customers place on speed to market, we distinguish ourselves with our comprehensive expertise, advanced equipment, and state-of-the-art facility, ensuring a seamless evolution from concept to prototype.

Streamlined Development Process

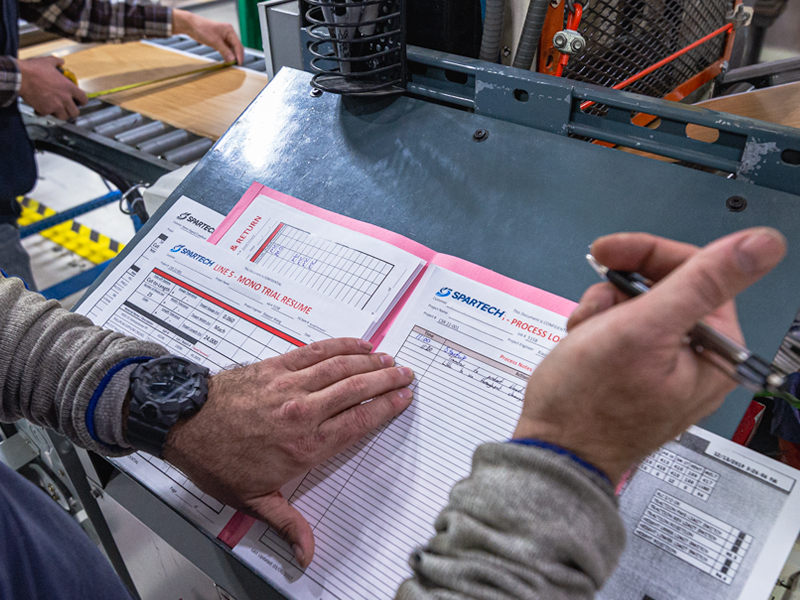

Our streamlined development process brings our customers' product visions to life, all under one roof at our world-class Innovation Center. Integrating our talent, skills, equipment, and facilities and offering them as a packaged service saves our customers the time and effort of managing multiple labs and facilities—reducing project complexity and expediting results.

Our Team: Expertise and Innovation

With a proven process, our team will design, test, and deliver customized solutions to meet our customers' unique challenges, guiding them through every step—from concepting to finished prototypes to mapping out the specifications for full production at one of our Spartech plants, or at the customer's production facilities.

John Vandeven, our Chief Technology Officer, oversees the Innovation Center. He values initial customer interactions, which reveal project expectations and issues, setting the stage for immediate solution development. John states, "Customers often start here with a preconceived idea, but through our collaborative process, they leave with a reimagined solution that surpasses their original concept. It's incredibly rewarding and a testament to our commitment."

We thrive on tackling complex challenges. Evelyn Xavier, Senior Chemist, emphasizes, "Creating customized testing solutions to address specific material issues, such as texture or durability, and validating these with objective proof is a crucial aspect of our development process."

Our Facility: Advanced Equipment and Capabilities

Located in St. Louis County, Missouri, our 90,000-square-foot Innovation Center is a premier facility in the industry. It is conveniently situated near airports and hotels and provides an ideal setting for on-site collaboration. The center is equipped with:

- Five extrusion lines.

- Film lamination capabilities.

- Over 50 in-house tools.

- Two thermoforming lines.

- Blown film and injection molding capabilities.

- Comprehensive lab testing for quality assurance, ranging from impact to accelerated weather and exposure testing.

Our facility also features conference rooms, meeting spaces, and training areas, fostering an environment where customers can work alongside our team throughout their project's development.

We maintain a diverse inventory of production materials and have the capacity to manage, store, and ship project-specific materials and finished goods efficiently.

Commitment to Excellence

Our well-coordinated and efficient system at the Innovation Center significantly reduces development time, enabling faster market entry for our customers. By accelerating the process while maintaining high standards, we save time and cost, aligning with our mission of optimizing product development.

Our Spartech team is here to help you achieve better results faster. Let us assist you in transforming your ideas into successful products through our expert prototyping services.

Contact us to talk with our team about your next project.

This blog is the second of two in our Innovation Center Spotlight Series.

May 24, 2024